Unique Features of BSTMX Bar Fe-550

Home | Product – TMX Bar

- BS TMX Bar SSO is made from 100% billets according to 1S: 2 8 3 0: 2 012, which is manufactured by a chemical controlled process and highest quality pure raw materials in a BIS, ISO, and ISl Certified Company.

- BS TMX Bar SSO is manufactured by the latest THARMEX QST German Technology in a Fully computerized PLC-controlled High-Speed modern rolling mill. This increases the flexibility of the bars, higher strength, greater load-bearing capacity, and a low percentage of impurities.

- Special advanced X rib design is made by a V-notch CNC computerized machine which ensures a 100% uniform rib pattern on the T MT bar. 45%more bond strength and 4.5 Tim e m o re Life (minimum) due to the unique X rib pattern this deformation makes it easy for concrete to grip the steel which gives the structure more stability and durability.

- Thin wire is used instead of loha kda in tying its bundle. With this, the customer gets more bars from 0.8 kg to 1.00 kg. Which saves about 500/ton.

- BS TMX Bar 550 has low carbon content and advanced elongation properties that ensure excellent yield strength and ductility, this bar is stronger than Fe 500 , these ores high in strength are used for high-rise buildings, dams, bridges, and heavy constructions.

- BS TMX Bar 550 is the mode with Thermax QST German Technology. Therefore, during on

- The tensile strength of this bar is a minimum of 10% or more, it has more strength as well as more flexibility.

- By keeping the amount of carbon and the carbon equivalent at a very low level, it has the ability to be better bending, joined with more flexibility.

- Its weight is kept very balanced. Its weight is kept between the minimum standard level and normal weight. That is, tolerance is produced in close proximity to the standard. That means saving along with safety.

- Due to more yield strength and more elongation of Fe 550 bar than ordinary bar, the re by saving on construction cost 15% to 20%of steel, that is saving Rs.700/ton.

- It helps in preventing fire accidents because up to 600-degree centigrade, there is no damage to the strength.

- It is produced by direct continuous casting and hot charging rolling (DCR) technology. Which saves energy. That is eco-friendly and cost-effective also.

- Having a protective oxide layer on the surface of the bar that protects from moisture and rust.

- Cover storage of finished goods to avoid corrosion due to rain and moisture.

- The 66-meter cooling bed gives more strength and proper flexibility to the layer (ferrite- peorIite, and martensite) of the bar at the temperature of the atmosphere.

- BS TMX Bar 550 meets the international standards ASTM, DIN, BS (BS:4449—2—2010), along with IS:1786: 2008.0

- BS TMX Bar 550 has Y / S minimum is 560 N/mm2 or more.

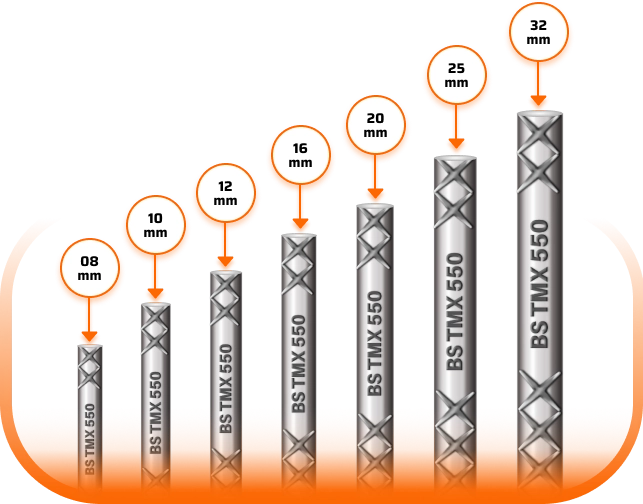

- The production capacity of the mill is very high. Range of Tmt bar available in 8 mm to 32