High-Quality Steel Delivered In Record Time

For Industry Professionals Seeking Reliable Steel Solutions, Delivered On Time, Every Time.

We have been using BS Group's BSTMX550 TMT bars for more than 5 years, and we have always been satisfied with their quality. For our projects, the hassle-free service have been a game changer for our projects.

Ashish Goel

Aaditya Enterprises, Raigarh

Our Products

Proven Durability, Guaranteed Satisfaction, and Superior Performance

BS Group excels in producing high-quality sponge iron, known for its excellent metal content, consistent properties, and low sulfur and phosphorus levels.

BS Group excels in producing high-quality billets, utilizing state-of-the-art technology to meet the highest

industry standards.

BS Group manufactures premium quality BS TMX Bars, known for their superior strength, flexibility, and durability, making them ideal for demanding construction projects.

BS Coils, known for their superior strength, flexibility, and precise dimensional properties, making them ideal for a wide range of industrial applications.

BS Group excels in producing high-quality sponge iron, known for its excellent metal content, consistent properties, and low sulfur and phosphorus levels.

BS Group excels in producing high-quality sponge iron, known for its excellent metal content, consistent properties, and low sulfur and phosphorus levels.

AbouT BS GROUP

Empowering Growth, Ensuring Quality!

Since its founding in 2000, B.S. Sponge Private Limited has been at the forefront of the steel industry in India, especially in Chhattisgarh and neighboring regions. Our facilities produce more than 1800 tonnes of sponge iron and 500 tonnes of TMT bars daily,Our commitment to innovation and reliability makes BS Group the partner of choice for dealers looking to succeed in a competitive marketplace.

Years of Expertise

Industries Served

Awards

Experience of

years

BS Group journey

Tracing Our Path to Excellence in Steel Manufacturing

2004

Expansion into Production

The company commenced production with an initial capacity of 30,000 tons per annum, setting a strong foundation for future growth. BS Group introduced Sponge Iron, marking its entry into the steel industry.

2019

Billet Production Launch

Production capacity was increased significantly, reaching 165,000 tons per annum. BS Group expanded its product line by launching Billets, further strengthening its steel manufacturing capabilities.

2020

BSTMX550 Launch

BSTMX550 was introduced, offering high-strength, corrosion-resistant, and earthquake-resistant TMT, catering to evolving construction demands.

2022

BS Coil Launch & Sustainability

BS Group launched BS Coils, marking another expansion in its product portfolio. The company also obtained ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications, reaffirming its commitment to quality, environmental responsibility, and occupational health.

2023

Ferro Alloys Launch

With a production capacity reaching 345,000 tons per annum, BS Group expanded its market footprint across multiple states, serving over 3,500 clients. The company also launched Ferro Alloys, further diversifying its product portfolio.

2024

BS Pipes Launch & Future Vision

BS Group introduced BS Pipes, catering to the growing demand for high-quality steel pipes. The company continues to innovate with plans to expand its manufacturing capacity, invest in R&D, and explore international markets, aiming to make India a global leader in the steel industry.

Why choose bs group?

Your Partner in Building a Stronger Future

High-Quality Products

BS Group is committed to excellence in producing high-quality steel products

Innovative and Adaptable

we continuously adapt to market shifts to offer the best solutions.

Reliable Supply Chain

BS Group ensures reliable product availability and faster delivery times.

Industry Recognition & Trust

BS Group has established itself as a trusted leader in the steel manufacturing sector.

Industry Leadership with BS Group

Leading the Steel Industry with Excellence and Innovation

Pioneering the Steel Industry

Our dedication to advancing industry standards and embracing cutting-edge technologies has established us as a benchmark for excellence.

Integrated Solutions for Diverse Needs

Our fully integrated operations empower us to provide tailored solutions for a broad spectrum of industries.

Driving Innovation and Excellence

We invest in research and development to enhance our products' quality and efficiency, ensuring that BS Group remains at the forefront of the steel industry.

bs group’s Transformative Impact

Real Impact: Case Studies Showcasing BS Group’s Excellence in Action

45% Increase in on-time project delivery.

Major Real Estate Developer

The client faced frequent project delays due to substandard steel leading to structural weaknesses which also led to a 15% increase in construction costs because of material wastage. BS Group Introduced high-strength TMT bars, improving structural integrity and provided customized steel grades, reducing material wastage.

Reduction in construction costs

Client Retention Rate

BS Group’s expertise in steel solutions helped us complete our projects ahead of schedule, saving time and costs significantly

Tuna Behera

Senior Engineer Quality

Tuna Behera

Senior Engineer Quality

50% Increase in Project Efficiency

Leading Automobile Manufacturer

The client faced frequent pipe failures in exhaust systems due to poor-quality steel, resulting in a 10% increase in rejection rates due to material defects. BS Group supplied corrosion-resistant MS pipes with advanced coating and optimized thickness, enhancing durability and eliminating defects without increasing costs.

Reduction in Maintenance Cost

Defect-free material supplied.

Switching to BS Group’s MS pipes completely eliminated our failure rate, ensuring our vehicles meet safety standards effortlessly

SWASTIK ENTERPRISE

Owner

SWASTIK ENTERPRISE

Owner

Hear it from the people

We are very happy to get client’s review!

Certifications

Showcasing Our Commitment to Quality and Standards

Blogs

Insights and Updates from the Heart of the Industry

Quality, trust, and local presence are important considerations when selecting reliable MS pipe steel producers in India, particularly for Chhattisgarh-based businesses. Whether you are sourcing for industrial, infrastructure, or construction projects, choosing the correct supplier guarantees value for money, performance, and longevity. The BS pipe, which is well-known for its strength and flexibility in a […]

The choice of the appropriate TMT bar for your project is one of the most crucial choices you will make when organising the construction of a home in Chhattisgarh, India. The durability and safety of your house can be significantly improved with a sturdy and dependable bar like the BSTMX550. Building quality is more crucial […]

For builders, contractors, fabricators, and industrial buyers, purchasing MS pipes in bulk is a major decision. A minor error in quality or specifications can result in significant losses in terms of money, time, and safety. For this reason, before placing any significant order, you must read this Bulk MS Pipe Buying Guide. MS pipes are […]

In growing towns like Uttar Pradesh, constructing robust and durable structures is of utmost importance. The quality of building materials has a big impact on longevity and safety in everything from industries and homes to schools and bridges. RustGuard TMT bars are among the most reliable materials available today, particularly grades like BSTMX550, which are […]

Specifically in India, the automobile sector is rapidly evolving. In order to create automobiles that are long-lasting, safe, and fuel-efficient, manufacturers are searching for stronger, lighter, and more affordable materials. High-strength hot-rolled steel, which is frequently supplied as Bs coil, is one commodity that is crucial to this transformation. This steel aids in enhancing overall […]

One of the most popular steel products in India, particularly in developing areas like Chhattisgarh, is mild steel round tubes. Materials like BS pipe are favored in industrial, fabrication, and construction projects due to their strength, affordability, and ease of use. Both huge infrastructure projects and small workshops employ mild steel round tubes. In order […]

One of the most crucial elements in creating sturdy and safe constructions is selecting the best TMT bar supplier, particularly in rapidly expanding areas like Chhattisgarh, India. The strength, longevity, and general safety of your project are strongly impacted by the quality of the TMT bars you select. Due to its exceptional strength and performance, […]

Because of their strength, durability, and affordability, mild steel (MS) pipes are among the most popular pipe materials in India. MS pipes are crucial when beginning a construction project, establishing an industrial plant, or working on a basic plumbing system. Because BS pipes are reputable for their long-term performance and quality, many consumers now seek […]

You’re not alone if you’re looking for TMT bar manufacturers in Uttar Pradesh that provide superior quality, dependability, and long-term durability. Strong and secure building materials are in greater demand than ever due to the fast growth of construction activities throughout India, particularly in areas like Chhattisgarh. One of the most crucial choices you can […]

The growth of top-notch HR coil producers around the nation is largely responsible for India’s rise to prominence in the steel sector. Particularly in industrial areas like Chhattisgarh, where steel manufacturing is vital to the economy, the demand for robust and dependable steel products keeps growing. Growing trust in Indian-made hot-rolled coils is reflected in […]

In terms of their strength, adaptability, and affordability, mild steel pipes are essential in the manufacturing and construction industries. Mild steel pipes are utilised extensively throughout India, particularly in areas like Chhattisgarh, which has emerged as a significant centre for steel and industrial development, whether you’re constructing a building, installing a water pipeline, or establishing […]

In the expansion of cities and the annual start of new infrastructure projects, India is growing quickly. A new urban India is being shaped by roads, metro lines, bridges, factories, and real estate developments, particularly in areas like Chhattisgarh, where industrial development is accelerating. TMT bars are now the mainstay of India’s urbanisation growth in […]

MS pipes are essential to contemporary plumbing, infrastructure, and building projects. Mild steel, or MS for short, is a substance that is well known for its affordability, strength, and durability. MS pipes are widely employed throughout India, particularly in developing industrial areas like Chhattisgarh, whether in tiny residential projects or major industrial sets. Engineers, builders, […]

550 vs 550D TMT Bar: How to Make the Right Choice The strength, lifespan, and safety of a structure are all strongly impacted by the quality of the materials used in construction. TMT bars are among the most crucial components for guaranteeing the stability of infrastructure and buildings. In order to choose the best option […]

The Future of Strong Steel in India: BSTMX550D In India, steel has long served as the foundation for infrastructure. Builders and contractors are continuously looking for stronger and more dependable materials due to the expanding demands of construction and the rapid urbanisation of the world. BSTMX550D is one of the newest advancements in reinforcement steel […]

The buyers frequently encounter the difficulty of locating a provider who strikes a balance between price, quality, and dependable delivery while searching for MS pipe prices in Chhattisgarh. Selecting the appropriate dealer is crucial for industrial, plumbing, and construction projects involving mild steel (MS) pipes. In Chhattisgarh, India, where building is increasing rapidly, BS Group […]

The quality of the materials used in building is essential to guaranteeing a structure’s longevity and safety. In Chhattisgarh, builders and contractors frequently search for trustworthy suppliers of premium building supplies, particularly TMT bars. BS Group has made a name for itself as one of the top TMT bar suppliers in Chhattisgarh out of all […]

One of the largest problems facing companies in India’s manufacturing and construction sector, particularly in Chhattisgarh, is waste and mistakes made without adequate technical assistance from suppliers. Inadequate technical assistance results in improper material use, production hold-ups, and higher project expenses. Because they don’t receive the proper guidance on how to use resources like sponge […]

BS Pipe by BS Group is the most dependable option for companies, builders, and contractors looking for a reputable MS pipe supplier in Chhattisgarh. BS Group has established itself as a prominent name in MS pipe distribution throughout India, particularly in Chhattisgarh, thanks to its solid presence in the steel sector and emphasis on high-quality […]

Afraid of Compliance Issues or Liabilities from Uncertified TMT Bars? Are you worried about uncertified TMT bars posing a liability or causing compliance problems? If so, you’re not by yourself. Builders, contractors, and homeowners frequently struggle to make sure the materials they employ match government safety and quality standards in India, particularly in Chhattisgarh, where […]

Industries around India search for suppliers who can ensure strength, durability, and prompt delivery when purchasing high-quality steel. The need for dependable steel products is always growing in Chhattisgarh, a state referred to as the “Steel Capital of India.” Businesses frequently choose the top HR coil suppliers in Chhattisgarh out of the various possibilities available, […]

The TMT bar price in Chhattisgarh is one of the most significant factors influencing project planning in India’s rapidly expanding construction industry. Homeowners, contractors, and builders all search for materials that are long-lasting and reasonably priced. Every strong structure is built on TMT bars, and the brand selection has a significant impact on both long-term […]

One name that often comes up in Chhattisgarh and throughout India when builders, contractors, or homeowners look for the top MS pipe dealers near me is BS Pipe. Any industrial or construction project requires careful selection of MS (Mild Steel) pipes, and modern consumers seek out solutions that are both economical and long-lasting. This type […]

The selection of steel is the most important factor for building sturdy and long-lasting structures in Chhattisgarh. BSTMX550 TMT bars are a reliable option among the several that are offered to engineers and builders. These bars are essential to guaranteeing the longevity and security of any building project because of their remarkable strength, flexibility, and […]

MS pipes are vital components utilised in a variety of industries, including infrastructure, water supply, agriculture, and construction, in today’s rapidly expanding industrial world. A significant centre for MS pipe production is Raigarh in Chhattisgarh, which is located in the centre of India’s steel-rich region. Among the several producers, BS Pipe has established a solid […]

The construction of safe and long-lasting structures in the construction industry requires the use of sturdy and dependable materials. Selecting the appropriate steel reinforcement is important for huge infrastructure projects, commercial structures, and residential dwellings. The TMT bar in Chhattisgarh, particularly the one made by BS Group, is currently one of the most reliable options. […]

One of the most important raw materials in the steel industry, billets are used to make high-strength products such as structural steel, wire rods, TMT bars, and more. The need for premium billets is continuously rising in Chhattisgarh, one of India’s major industrial regions. BS Group, one of the top companies in this field, has […]

Sturdy materials are necessary for sturdy foundations in the construction industry. TMT BARS, which are renowned for their resilience to harsh environments, flexibility, and durability, are among the most important materials utilized today. The need for premium TMT bars is continuously increasing in India, especially in Chhattisgarh, as a result of the state’s rapid infrastructural […]

BS Group has established itself as a reputable brand in Chhattisgarh and throughout India for premium MS pipes. BS Group, one of the top producers in the area, is renowned for creating mild steel pipes that satisfy the strictest requirements for durability, dependability, and affordability. Because BS Group’s MS pipes are made to last in […]

The performance and durability of industrial manufacturing and construction in India, particularly in Chhattisgarh, can be significantly impacted by the choice of material. Because of its unparalleled quality and strength, BS Coil has grown in popularity among these materials. Premium-grade HR coils are crucial for applications in machinery, automobiles, and infrastructure. The best characteristics of […]

We build relationships that inspire success

Whether you’re looking to start a new project or need support for ongoing ventures, we’re here to offer expertise and solutions that help you excel. Join us in crafting a future where your aspirations are our priority.

Social Media

Follow us on social media @bsgroup_raigarh

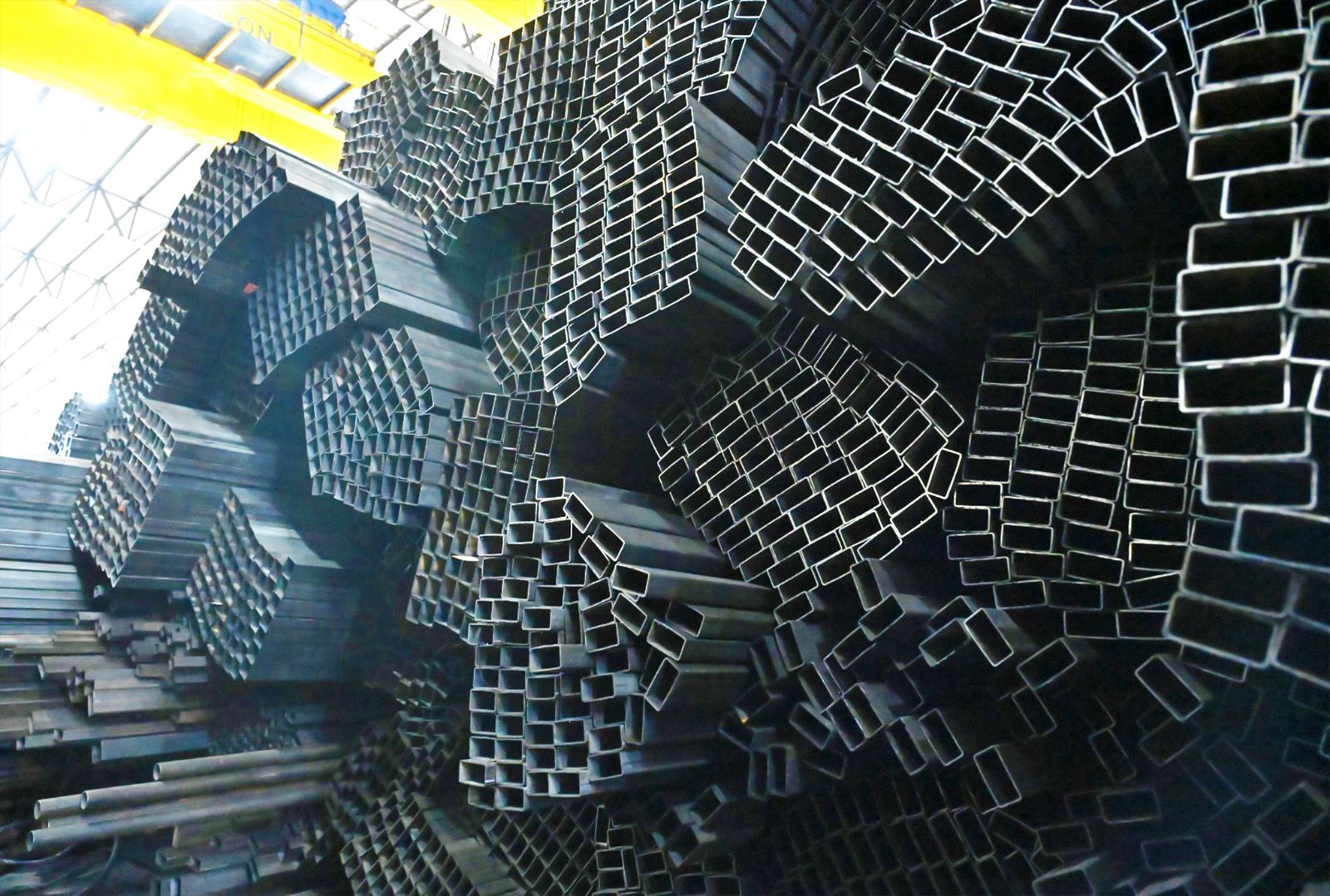

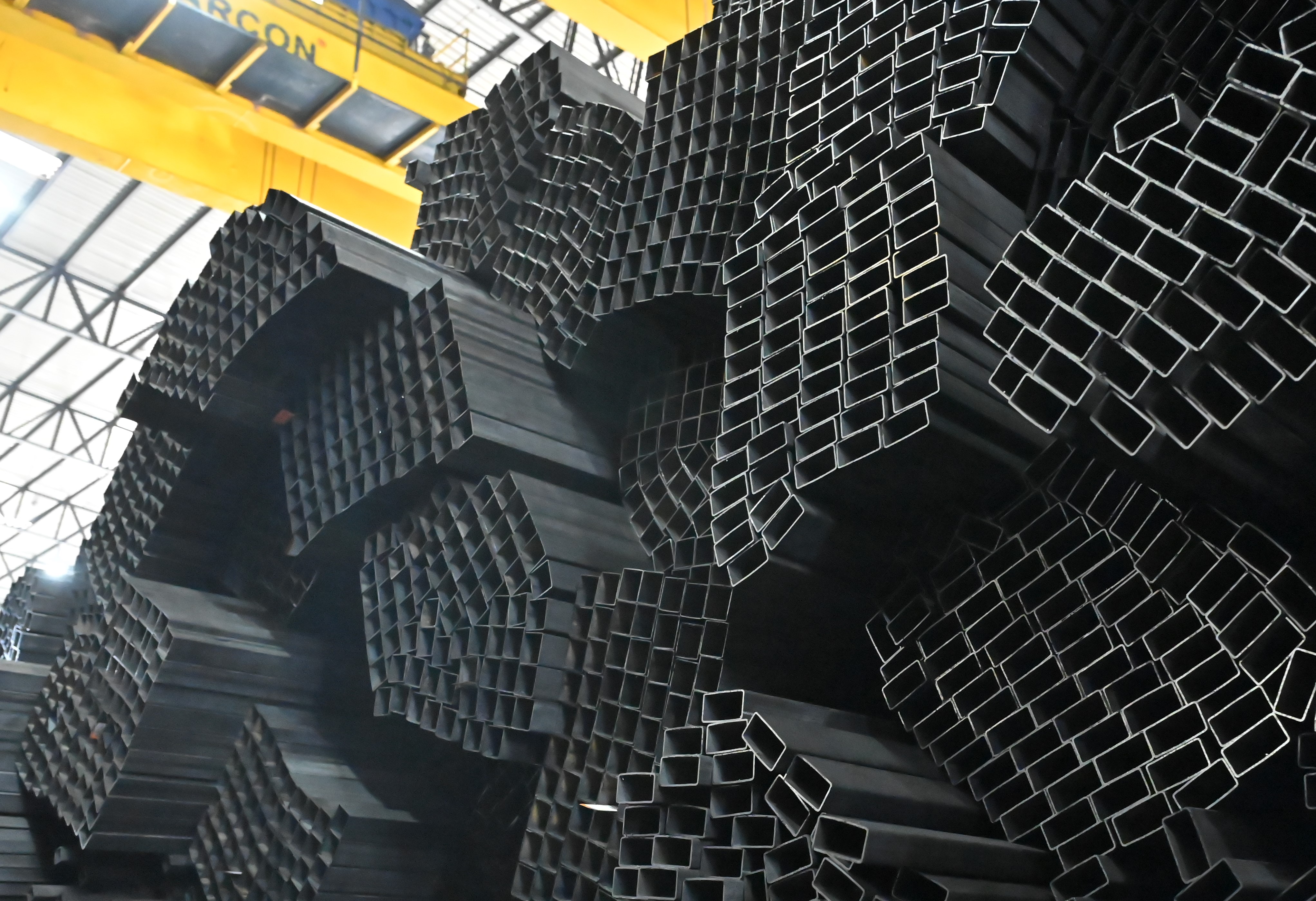

Our Production in Pictures

A Closer Look at the Processes That Define Our Excellence