Our Features

Home | Product – Our Features

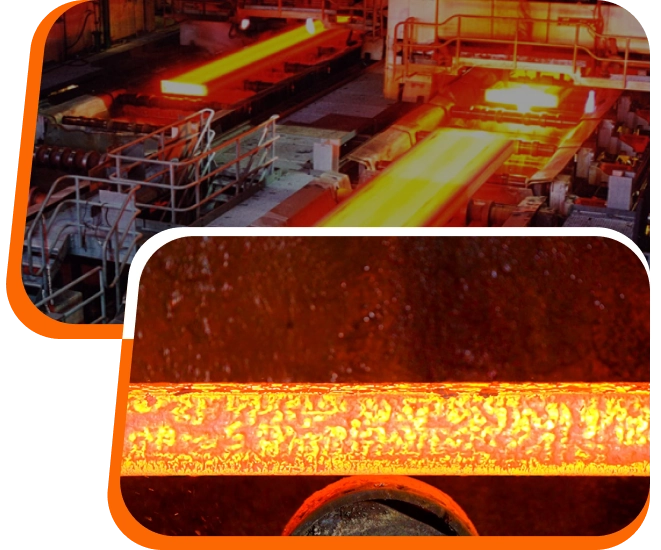

Features of Rolling Mill

B.S. Group’s state – of – art Rolling mill technology comprises a roughing mill of 2×14 stands, a total continues up to finishing stands equipped with auto-tuning channels and auto power press cutting and bending machine. The machine has 15 individual DC motors for total automation. It is the ideal solution for planishing and grinding various types of steel bars. Moreover, it can also be used for deformation machining operations.

Product Features

- Premium German design ensures durability.

- Fully automated system with easy operation.

- Retrofit option available.

- Non-smoke, no odor

- Roll steel strips into round bars.

- Features automatic cutting, bending, and rolling in one unit.

- Easy operation; motorized transfer Rod & Control panel

Features of THERMEX QST German Technology

Thermax Qst German technology is a system used by several hundred mills in India and over the world. The processing of TMX bar through this process gives its name “Tmx Bar” which is superior in strength and has higher resistance against Natural phenomena like earthquakes etc.

Tmx Bar is a high-quality Bar process with Thermax Ost German tech. We B.S. Group manufacture the best quality heavy-duty structural steel bar in central India & Chhattisgarh. BSTMX bar is a strong and highly resistant quality material used in various construction projects

It’s specifically designed to withstand the effects of earthquakes and other resistance features

Advantages of THERMEX QST German Technology

- Excellent Ductility: Due to uniform grain.

- Excellent Weldability: Due to low carbon equivalent.

- Excellent Bendability: Due to controlled process.

- Excellent Bond Strength: Due to uniform & precise ribs.

- Excellent Fatigue Resistance: Due to high UTS/YS ratio.

- Excellent Earthquake Resistance: Due to a higher percentage of elongation.

- Excellent Resistance to Corrosion and Fire: Due to highly controlled chemistry.

Features of Cross Ribbed Tmx Bar

Why Is Cross Ribbed TMX Bar Useful for Construction?

The bar has several features that, when combined, offer maximum strength and durability to RCC structures. this bar with cross-ribbed patterns was introduced to provide better bonding with concrete. The deformed patterns provide a better grip with construction materials. This bar has a particular pattern on its outer surface called ribs and lugs or cross-ribbed patterns. the specific pattern comes in several variations and is decided according to how the TMX bar will be used and the properties that are most desired. This enhanced grip is crucial for keeping the structure intact during natural calamities such as earthquakes or floods when the stability of structures can reduce the loss of life and property.